Innovative engineering solutions for tomorrow's challenges

We provide cutting-edge engineering services tailored to meet the specific needs of modern industries. Our team of skilled engineers brings expertise across multiple disciplines, ensuring we deliver comprehensive and customized solutions that drive operational success.

Our core engineering services

Engineering & automation solutions

We specialize in designing and developing comprehensive systems that combine mechanical, automation, and control elements. From initial concept through to final implementation, our engineers ensure optimal performance, reliability, and seamless integration.

- Product Design & Prototyping: Transform your ideas into reality, with prototypes designed to meet rigorous performance standards.

- Automation & Control Systems: Automation & Control Systems: Implement advanced systems to automate operations and enhance efficiency across your business.

- System Integration: >System Integration: Integrating new technology into your existing systems with minimal disruption, ensuring smooth operations

Custom automation solutions

Our expertise in automation allows us to design scalable, future-proof systems that cater to your business's evolving needs.

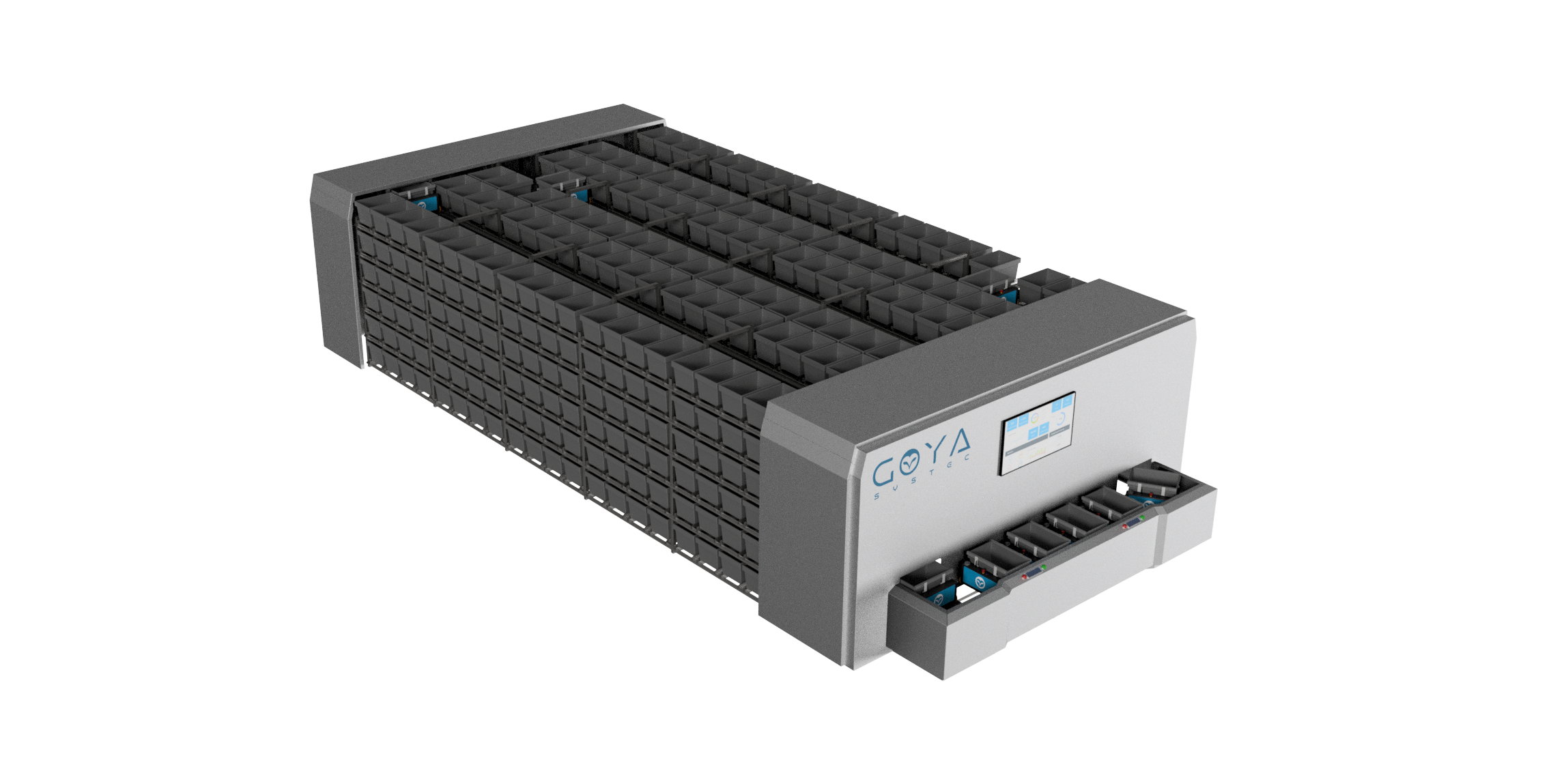

- Automated Storage & Retrieval Systems (AS/RS): Automated Storage & Retrieval Systems (AS/RS): Efficient storage systems that optimize space and improve inventory management.

- Robotic Systems Design: Robotic Systems Design: Automation solutions tailored to reduce manual labor, enhance precision, and improve overall process efficiency.

Project management

We offer end-to-end project management services, delivering projects on time, within budget, and to the highest quality standards.

- Consultation & Planning: Consultation & Planning: Close collaboration with clients to develop strategic plans that meet project goals.

- Implementation: Expert supervision throughout the implementation phase ensures all elements are completed to specification.

- Support & Maintenance: We offer continuous post-deployment support and maintenance to keep systems running at peak performance..

Mechanical & Control Engineering

We deliver intelligent systems through the integration of mechanical hardware and electronic control, combining precision motion with automation intelligence.

- Design and integration of mechanical and electronic systems

- Control software, robotics, PLC, and CNC

Intralogistics & Automation

Our intralogistics solutions streamline internal material flows using smart, automated storage and handling systems to boost efficiency and scalability.

- Shuttle and stacker crane systems

- Conveying systems and automated storage

- Development of proprietary AS/RS solutions like Storingo – a mobile, modular, autonomous mini-fulfillment system

Research & Simulation

We apply advanced simulations and data analysis to validate system designs, predict behavior, and ensure performance before physical deployment.

- Data-driven feasibility studies

- Statics, flow, and FEM simulations

Prototyping & Manufacturing

From functional prototypes to final products, we transform designs into reality using a mix of in-house engineering and trusted manufacturing partners.

- Rapid prototyping and manufacturing via trusted local partners

- Combination of in-house design and outsourced production

Testing & Validation

We ensure every system performs as intended through rigorous testing, stress validation, and quality assurance protocols before deployment.

- Functional and load testing

- Ensuring reliability and robust system performance

On-Site support

Our field engineers provide full on-site support, from system installation and commissioning to fault diagnostics and quality assurance.

- On-Site installation

- Commissioning

- Root-cause analysis

- Quality check

Documentation

We provide detailed technical documentation, manuals, and procedures to support seamless system integration, operation, and maintenance.

- Complete technical documentation

- Integration and maintenance manuals

Our Approach

- Needs Analysis – Define goals and initial research

- Concept & Simulation – Feasibility studies and iterative design

- Prototyping – Functional validation through mockups or pilot units

- Testing – Load and performance testing

- Implementation – On-site or remote commissioning

- Documentation – Technical files and training material

Technical Innovation & IP

We hold patents for shuttle systems and warehouse automation technologies, such as modular shuttle designs and container handling systems. Our solutions are designed to optimize automation efficiency and scalability.

References & Network

- Participation in LogiMAT 2025 with key insights and demonstrations

- Collaboration with European industry leaders

- Growing LinkedIn community with over 260 followers

Contact & Collaboration

- Flexible project models: hourly, work-package, or full-project

- Worldwide support: remote or on-site

- Free 'Engineering Challenge' offer: up to 3 realistic suggestions per request

.JPG)